Industry 4.0

Building the next generation of marking technology for brand protection across the supply chain

We work hard to deliver our own comprehensive marking technology systems and also revolutionize brand protection by keeping products authentic, safe and connected across the supply chain.

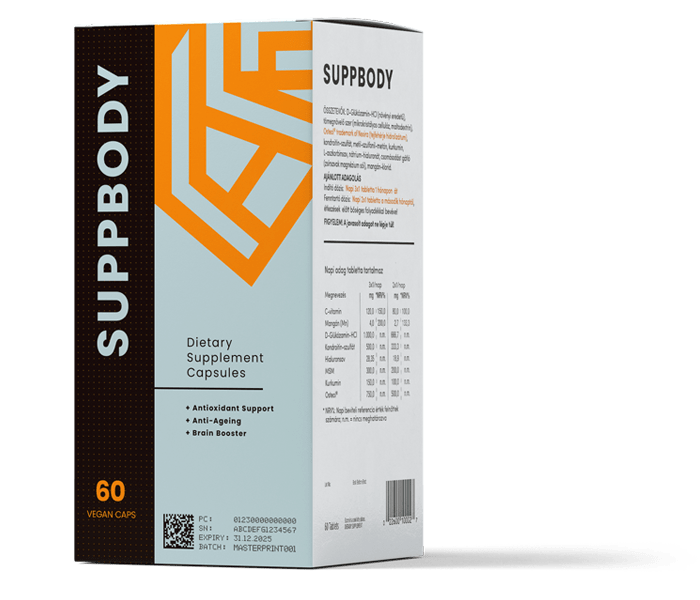

Product serialisation for different industries

Counterfeit products, which are continuously appearing on the market and usually imitate the appearance of genuine brands but fall far short of industry quality standards, are a serious risk to the pharmaceutical industry worldwide. If they contain any active substances at all, they do not contain the required amount, which in some cases can make them life-threatening for their end users.

Just as in other segments of the chemical industry, agrochemistry can also benefit from state-of-the-art Track and Trace methodologies that provide effective solutions to a number of sector-specific challenges. Thanks to unique identification, the entire life cycle of products and raw materials can be tracked, ensuring that the levels of pesticides and other chemicals in food are kept within the limits set by health regulations.

Quality assurance has become a priority in the food industry, and as a result of this the importance of traceability of goods has also increased. As the free movement of finished products and raw materials between EU member states has made the supply chain system much more complex, tracing and recalling the source of possible contamination or raw materials that could be harmful to health has become a much greater challenge. This problem can be addressed by serialisation in the food industry. Serialisation allows the life cycle of each product to be tracked and retrospectively controlled at every point in the production and logistics process, from farm to fork.

With custom marking systems, we can coordinate the hardware and software aspects to create a comprehensive solution for printing tasks in any industry. In addition to labellers, assemblies like this can include serialisation and aggregation stations, robotic cells, automated measuring and labelling systems, scales or quality control cameras.