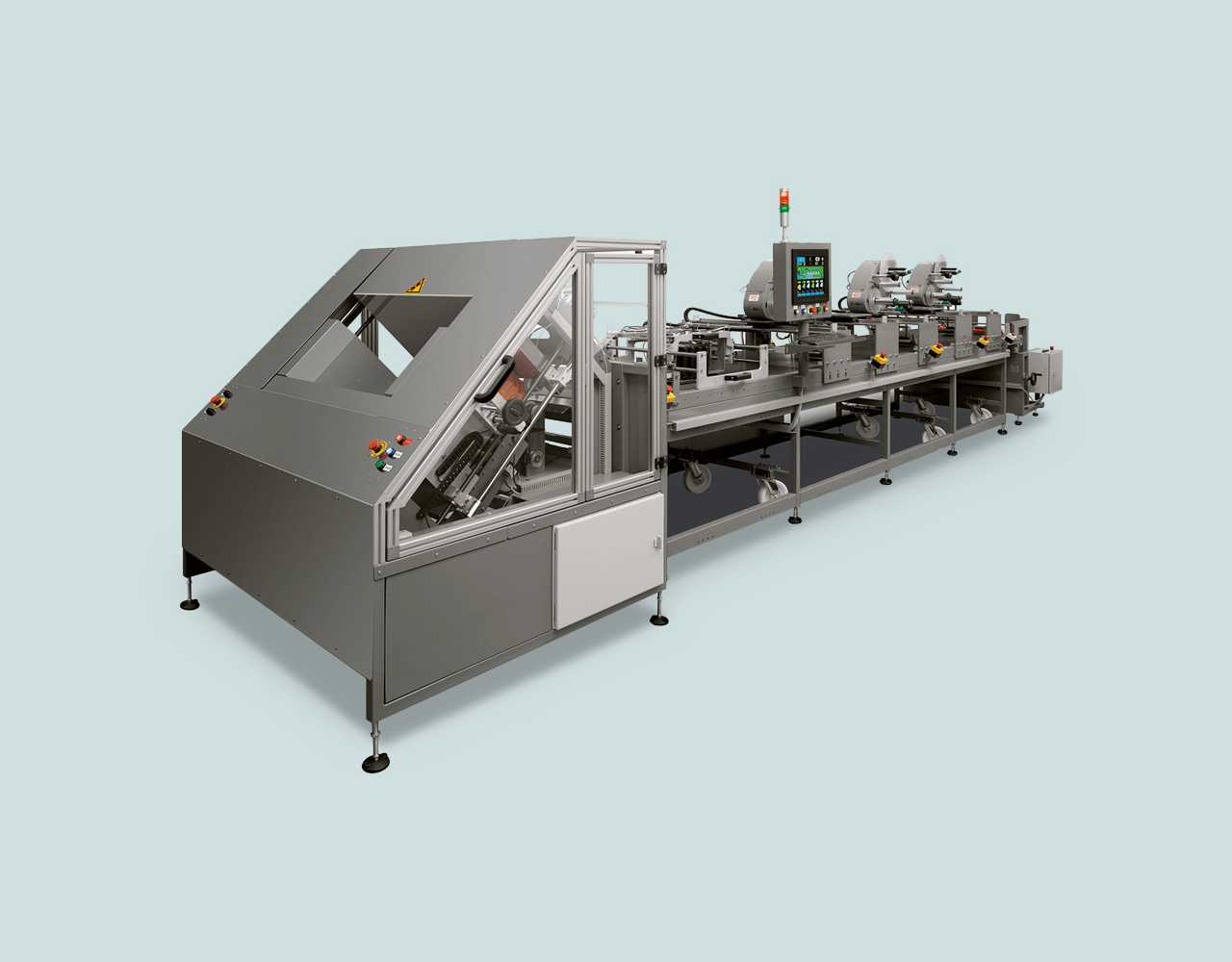

When developing the bagger and labeller, we placed great emphasis on ensuring that the operation of the line requires minimal maintenance and therefore the least possible human resources to promote production efficiency. The automated process consists of the following steps:

1, Feeding

Our uniquely designed automatic bag feeding machine has a maximum capacity of 150 bags, but can be continuously loaded to avoid downtime losses. Compatible bag sizes: height: 380-550 mm; width: 550-900 mm.

2, Marking

The bags can be optionally labelled by two Matthews VIAJet T100 or two, three or four Matthews L50 thermal inkjet printers. The marking speed can be up to 100 metres per minute depending on the setting. The character size can be adjusted from 2 to 100 mm and the maximum print height is 100 mm.

3, Labelling

For the labelling of bagged products, a total of five stations can be integrated into the system, in a customised configuration, which can be assembled from the following devices:

- Novexx ALS 206 uses an easy-to-replace roll of material to apply your pre-printed design labels and folding tags.

- Novexx ALX 735 is a high-performance system for labelling and applying your pre-printed labels subject to strict tracking requirements. This machine is capable of intelligent variable data management and high-quality printing.

- With the addition of a separate applicator, the Novexx ALS 206 uses air to apply the design labels to the bags, rotating them 90 degrees to the direction of travel.

4, Bag sorting unit

The final step is for the marked and labelled or tagged bags to be sorted by a unit with a sensor that can be adjusted to the size of the bags.