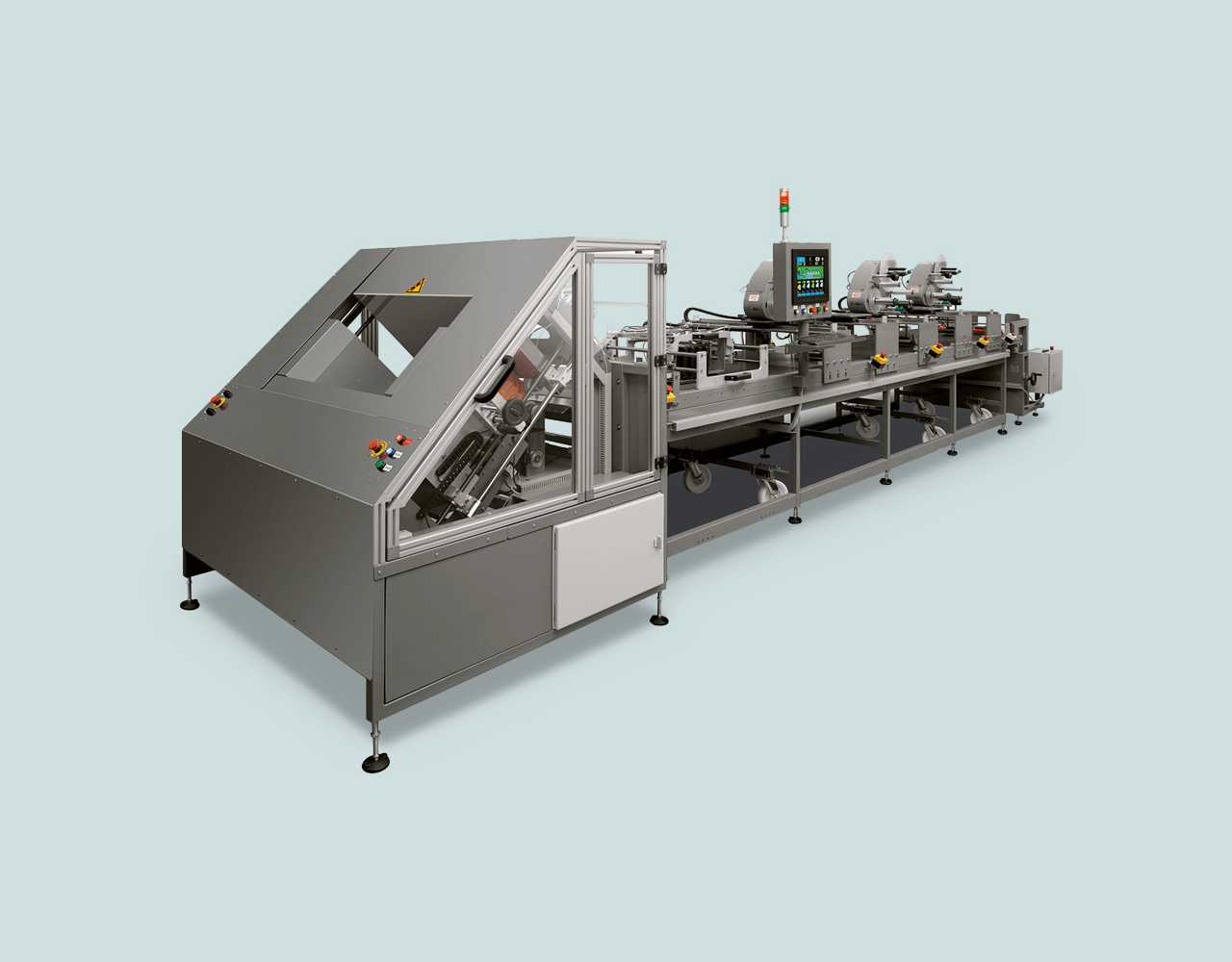

A conveyor belt tracking the distance between the products

In order to ensure certified measurement, it was important to have a belt regulating the distance between the products, because only one piece of cheese can be put on the belt at a time. This belt allows the product to be measured only at the regulated distance and speed.

Ishida belt weigher (certified) with integrated CEIA detector

Ishida is a producer with several years of experience, weighing in a credible and sufficiently precise manner, that transfers the data with fast data communication. Ishida was an obvious choice since our sister company, MasterQuality Kft. is the exclusive distributor of the Ishida products, and the quality was already proven on several occasions. Considering the high sensitivity of CEIA metal detectors we can state that CEI is one of the best among these products.

Novexx ALX 924 with a top labelling application

We have installed a Novexx ALX 924 top labelling device in the system, a product with an appropriate price/value ratio and high printing quality. As the size and shape of the products are continuously changing, we have designed a unique label applicator for this, so that it can be used for label any type of cheese product.

Novexx ALS 206 bottom labelling device

Once the top label with various data is fixed after the measurement, the standard label can also be put on the product.

4 stage selection/sorting station

Besides measurement and labelling, sorting function was also required. Products can be sorted based on the defects (weight is lower or higher than required, metal contamination, other defect) or according to weight. It can be set that after measurement and labelling, products less than 1 kg will go to box No 1, products between 1 and 2 kg will go to box No 2, products between 2 and 5 kg will go to box No 3 and defected products will go to box No 4.

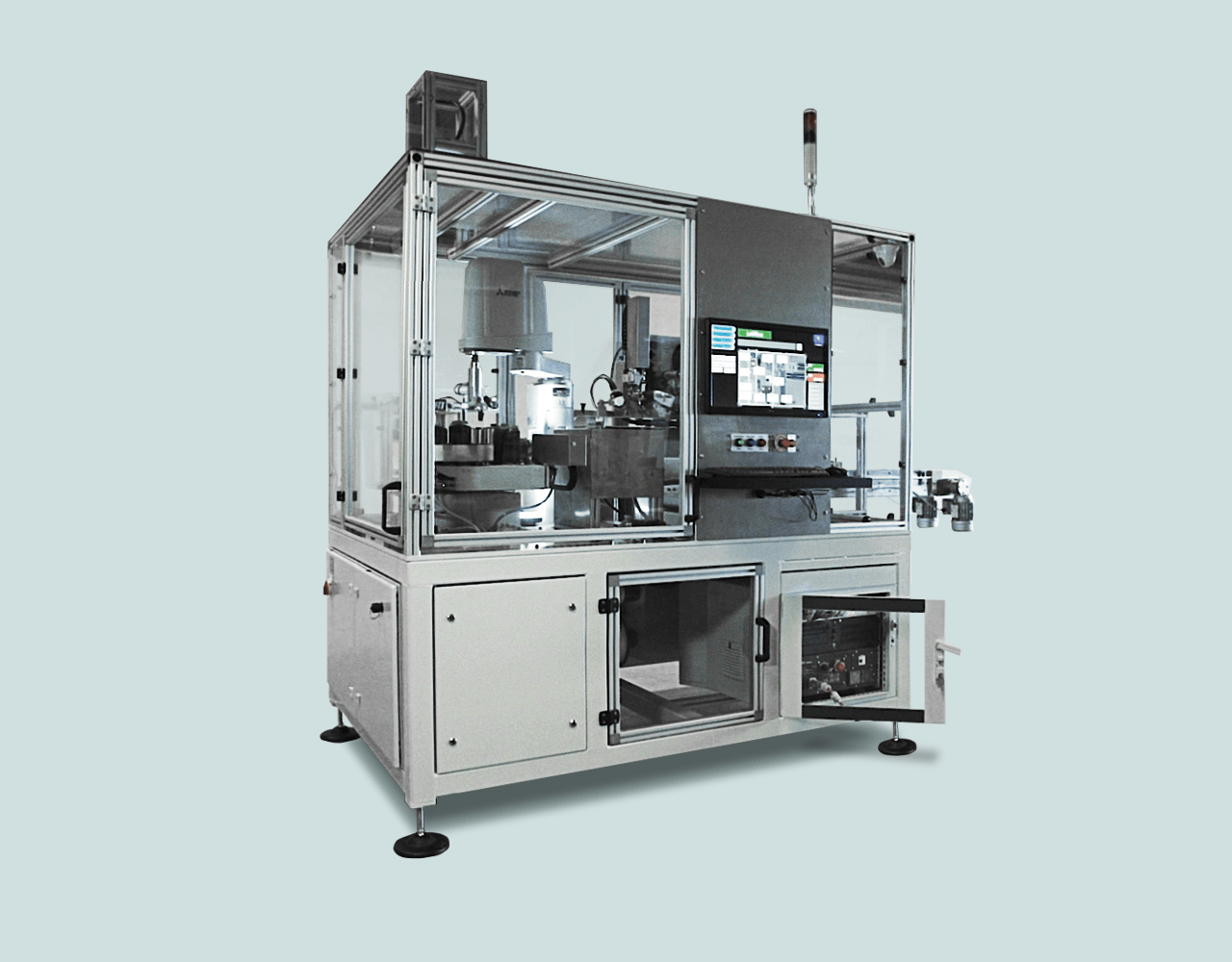

Automated printing of aggregating labels for packages, boxes or pallets

The data of the aggregate labels include the data of individual measurements, where after the automated label printing phase, the label is put manually on the products. The content of the aggregate labels can be freely configurated, the system can aggregate cheese in any type of geometric features.