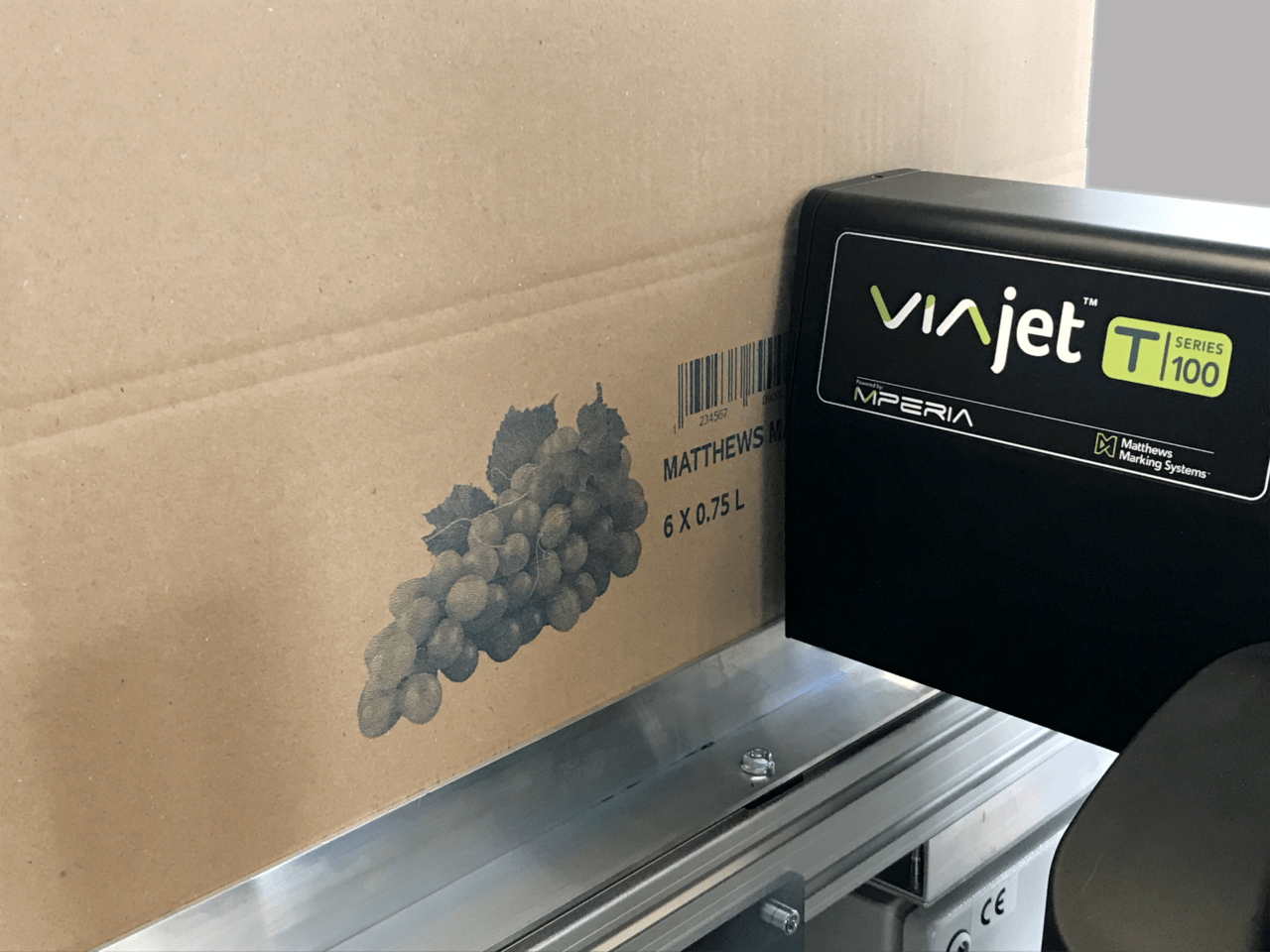

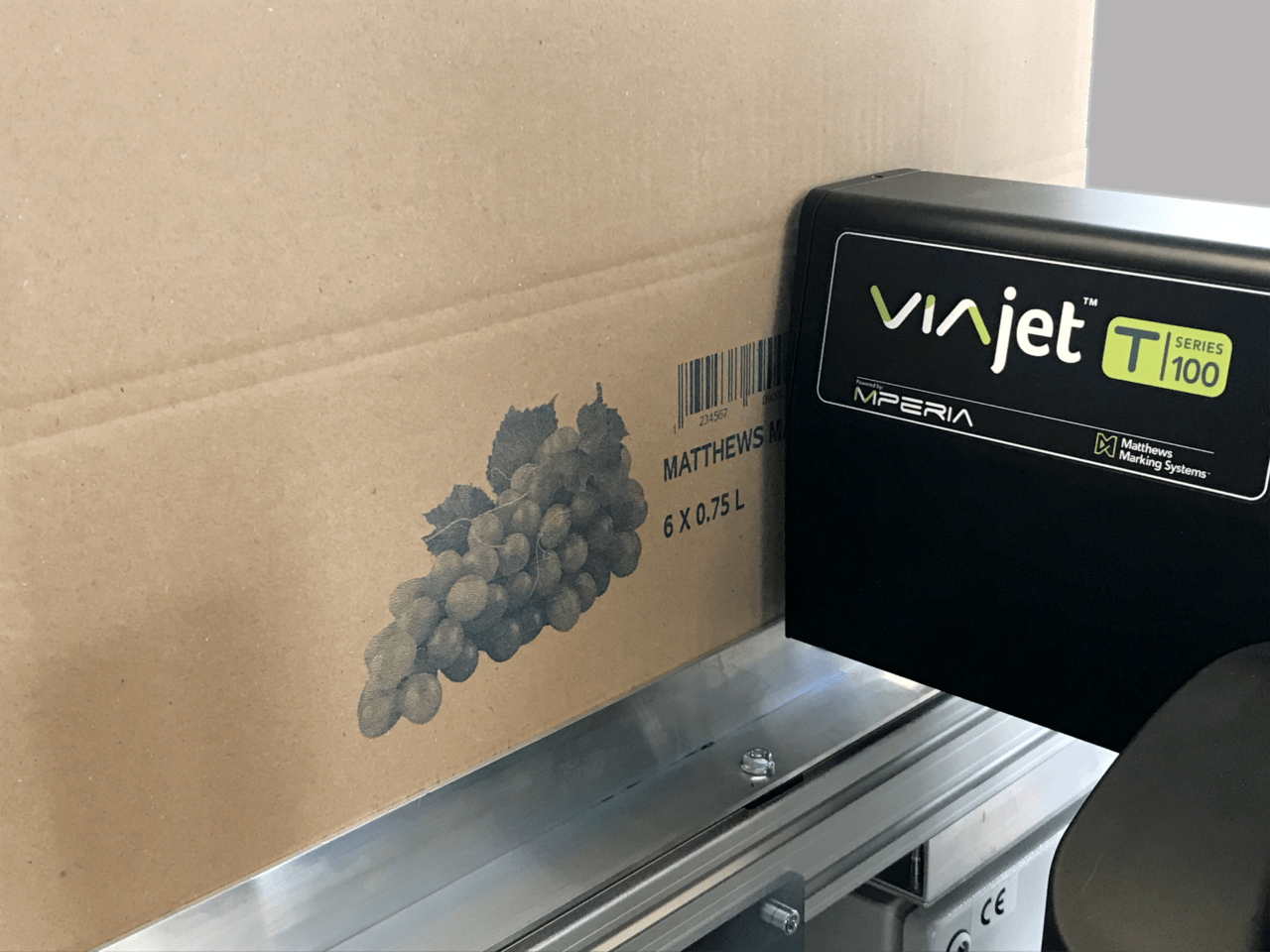

High-resolution and optionally large-sized markings

Barcode, QR code, micro QR code, DataMatrix code, images, and graphics placement – none of these pose a problem for the T-Series inkjet coders. Designed to allow for various label font sizes, facilitating the coder’s application to the production process. Pre-printed boxes are always more expensive than direct printing on the production line. Additionally, for cost-effectiveness, Matthews markers are capable of printing the largest print area among industrial printers, allowing for the creation of larger quantities of prints with fewer printheads.

Suitable for both smooth and corrugated surfaces

The T-Series coders can print on a wider range of substrates compared to their conventional counterparts. They are suitable for marking secondary packaging, such as cardboard boxes, corrugated cartons, and trayed packages. They are also used for primary marking of timber products and other porous surfaces, with minimal ink wastage thanks to the recirculating ink feature. Faced bad experiences with label printers? Changed information to be placed, but boxes have already been pre-printed? Direct box printing and the MPERIA® system can save money and avoid long downtimes.

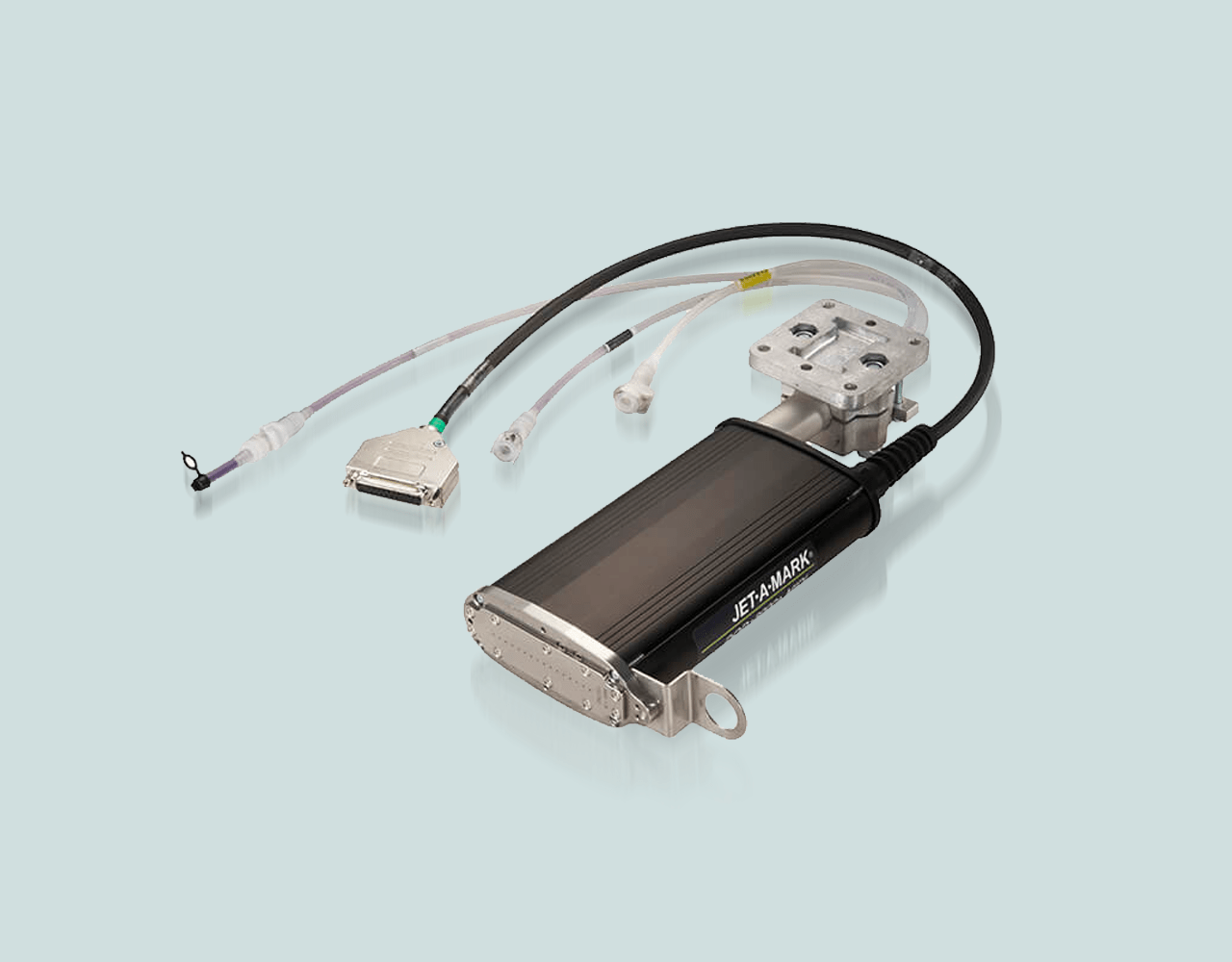

Durability and a wide range of ink options

Piezo printheads are extremely durable, as they are not subject to heat-induced functional degradation, unlike thermal inkjet systems. They can also be used with inks that would alter material properties under heating. Compared to thermal inkjet systems, piezo-based printers can utilize higher concentration inks and binders. Piezo printers operate without heat, allowing for a much wider range of ink types compared to traditional coders, including pigment inks and heat-sensitive inks.

User-friendly interfaces

The development of a 7 to 15-inch touch screen control interface ensures easy input and editing of messages, comes with a virtual simulator, and is highly advantageous due to its easy network integration. It can also be controlled remotely via VNC. Its Ethernet-based connection allows for integration with various enterprise resource planning systems, computers, and programmable logic controllers.

One of the technology’s advantages is high speed

Printing 5 to 10 cm high characters, up to 84 meters of text per minute horizontally or vertically – this characterizes the Matthews VIAjet T-Series inkjet markers. Thanks to the MPERIA® universal controller, capable of managing multiple production lines simultaneously, it helps avoid not only long downtimes but also losses resulting from human errors and omissions. The series can be equipped with Matthews Marking System EasyCode™ inks, which have a long shelf life, lasting up to 18 months before use, ensuring an available supply of every needed color. These inks are suitable for both porous and non-porous surfaces. The AccuScan™ inks, also developed by Matthews, are highly pigmented in black, blue, and red colors, and their main advantage lies in their exceptional resistance to heat and moisture. These inks are also usable for up to 18 months.