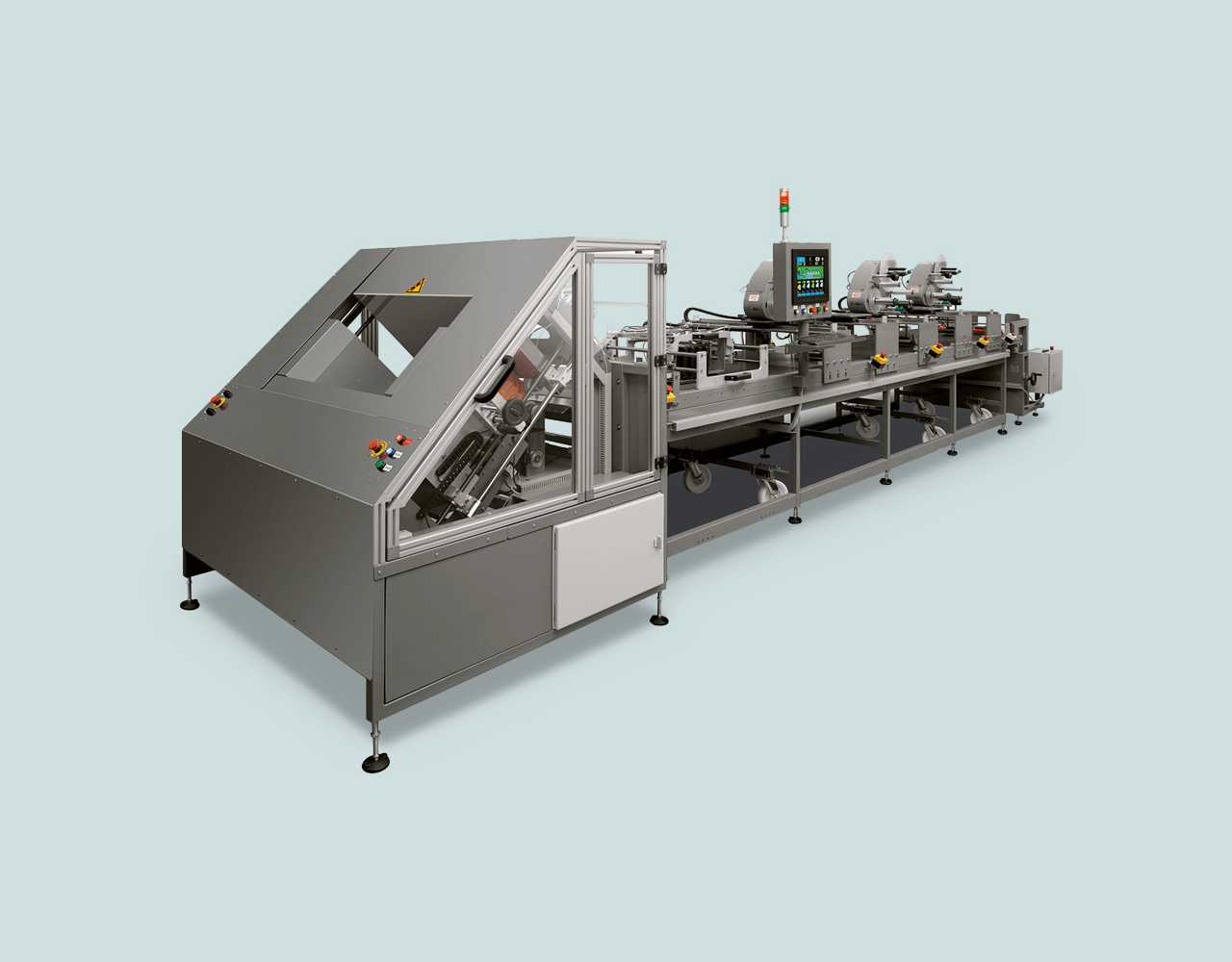

How can a machine print on a concave surface so that the characters are perfect? And if some of the labels are distorted and the labelling is illegible, should the product be rejected?

When we buy a product in an aluminium bottle, we rarely look at what is written on the bottom. But it is a major challenge to develop a printing system that can reliably place markings with minimal distortion on the bottom of bottles with curved, concave, shiny or reflective surfaces. The task becomes even more difficult if the client’s request is supplemented by the need to have the label checked by a camera system, in line with pharmaceutical industry standards.

Because of the special printing surface, we had to be even more precise than usual, and the fact that the characters to be placed are very large didn’t make the task any easier for our developers. It was made even more difficult by the fact that the concave surface on the bottoms of the bottles do not curve uniformly: the centre is quasi-flat, and the angle of inclination changes slowly at first, then abruptly as you move towards the two edges. As a result, the large characters can become more distorted at the edges than in the middle, and the amount of distortion also varies depending on the diameter of the bottle.

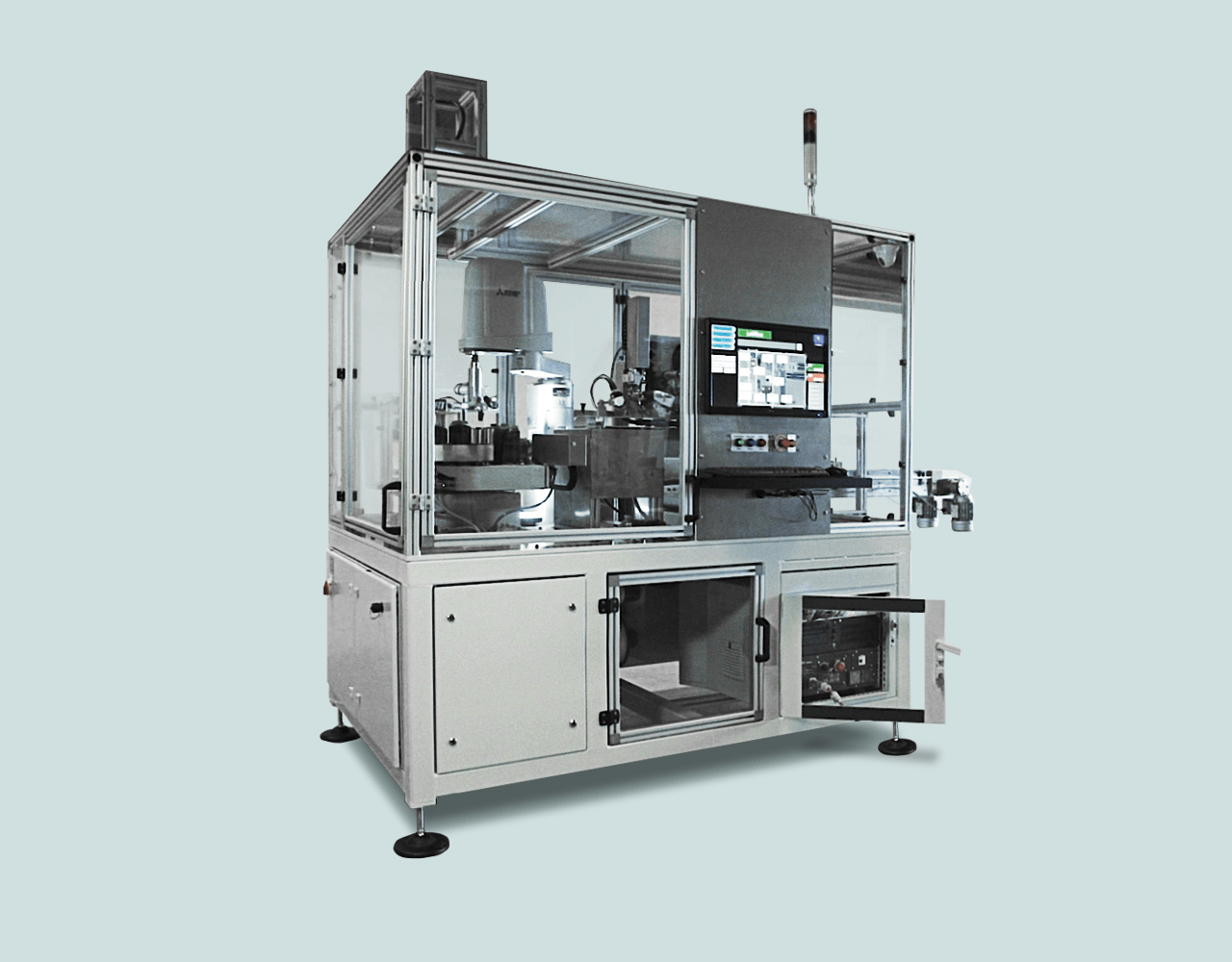

The solution was a two-step system. The printing is performed by the Leibinger JET3up small-character inkjet printer. An Omron camera decides whether the printing has been done properly: it reads back the character sequence from the curved surface one by one and decides whether the labelling is correct or whether the bottle should be rejected. In effect, the computer checks an image processed by a complex algorithm and selects the boxes based on this.

The camera is supported by a custom-designed backlight built into a 3D-printed frame made of a special material, so the curved surface it scans will never be in the shade.