The Printess 4 is a compact and cost-effective label printer and applicator with a maximum print size of 107mm x 500mm. The Printess 5 model stands out for its independent operation, as it can accommodate up to 1000 meters of ribbon due to its large diameter. This reduces the frequency of ribbon changes and increases efficiency. The maximum print size for this model is also 107mm x 500mm. The Printess 6 is designed for A5-sized labels, primarily for pallets, with a maximum size of 160mm x 500mm. The Printess 8, on the other hand, is designed for even larger A4-sized labels (210mm x 300mm) for printing and application.

Labeling from multiple directions

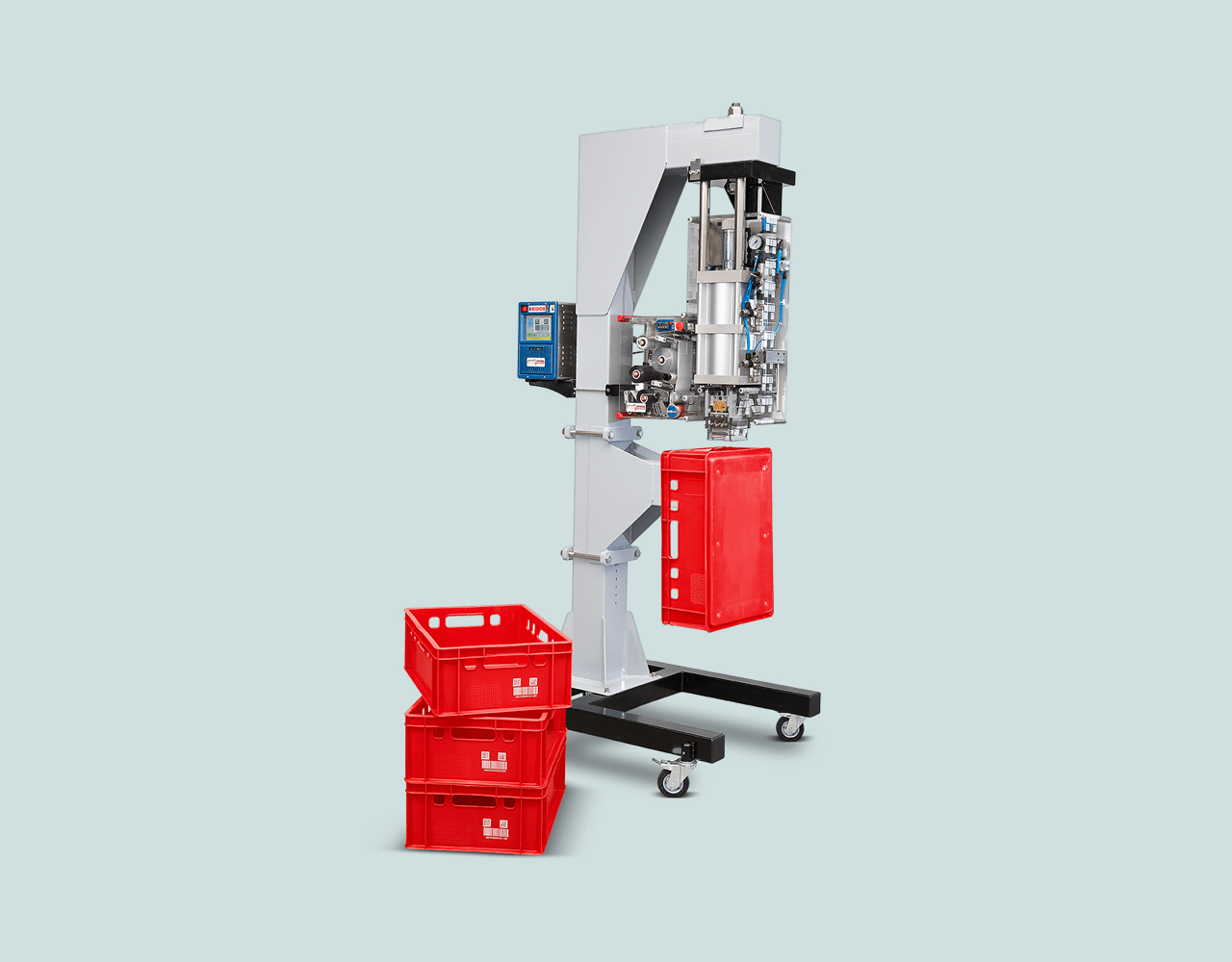

The modular design of the Eidos Printess series allows for easy interchangeability of various applicators developed for different tasks. The Printess thermal transfer printers, equipped with the Rotor automatic applicator, apply labels on two adjacent sides of vertically positioned boxes, while the Rotor Fast applicator applies labels to moving boxes on the production line. Eidos is also capable of providing custom solutions for complex situations, such as the In-Spool applicator designed for placing labels inside tubes.

Easy integration

The Printess series can be seamlessly integrated into existing software used by the company, making it easy to incorporate into production processes. It is an ideal choice for printing variable data such as dates, ingredients, barcodes, 2D codes, and applying labels. Data can be input via the touchscreen, connected computer, USB flash drive, or directly from the printer’s memory. The EASYCODE software allows for easy creation and editing of label information.

Pallet labeling

The Printess 6 (A5 size) and Printess 8 (A4 size) series automatically apply large-sized labels on one or more sides of pallets at the end of the production line. The pallets can be stationary or in motion, and the labeling options include:

- One side of the pallet

- Front and side

- Front, side, and back

- Labels can be applied on the strapping bands that secure the pallets

Box labeling

The Printess 4 and Printess 5 series automatically label boxes and bundles moving at medium to high speeds on production or packaging lines. Labels can be placed on:

- Front of moving bundles

- Sides of moving boxes

- Front or back of moving bundles

- Front and back of moving boxes

- Sides or top of stationary boxes

- Corners of stationary boxes with large-sized labels

Labeling materials

The Printess 4 and Printess 5 series can accurately apply labels on stationary objects with proper pressure and precision. The use of plastic labels and thermal transfer ribbons enhances the durability of the labels. The Printess 4 is the most compact and cost-effective label printer and applicator, suitable for placing small to medium-sized labels (up to 120mm wide and 500mm long). It is available in both right-handed and left-handed versions. It prints at a resolution of 300 dpi with a maximum print speed of 500mm/s.

Printess 5 – Larger diameter

Efficient printing and labeling are achieved with larger label and ribbon diameters, allowing for the loading of up to 1000 meters of ribbon. It operates at a resolution of 300 dpi with a maximum speed of 500 mm/s.

Printess 6 – For labels up to 180mm wide

Designed for labeling A5-sized pallets with a size of 150mm x 210mm, it operates at a resolution of 300 dpi and a speed of 400 mm/s.

Labeling pallets and barrels

It prints and applies A4-sized labels with a maximum width of 210mm and a length of 500mm. It operates at a resolution of 300 dpi with a lower speed of 200 mm/s.