Who is PharmaJet DMP6 recommended for?

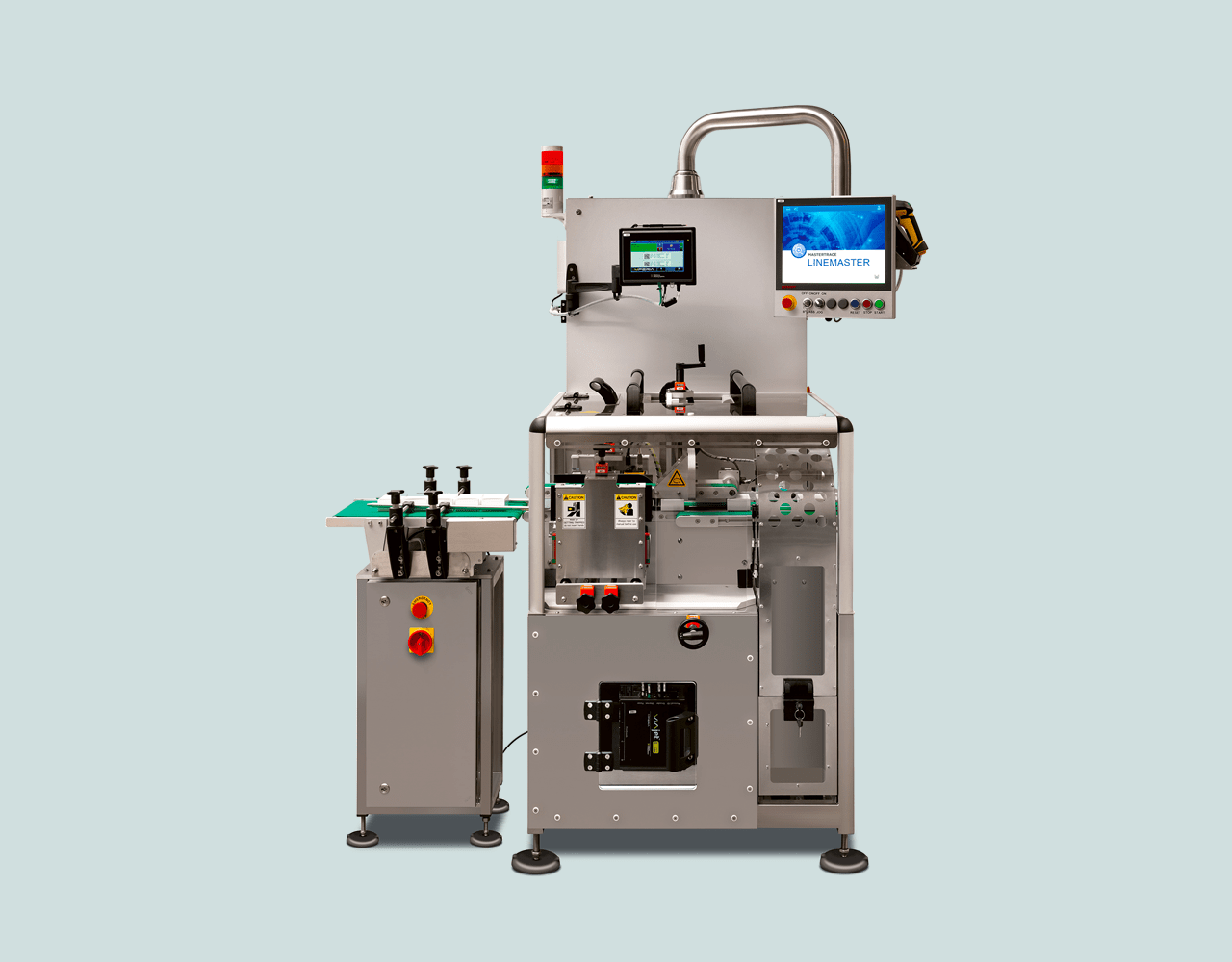

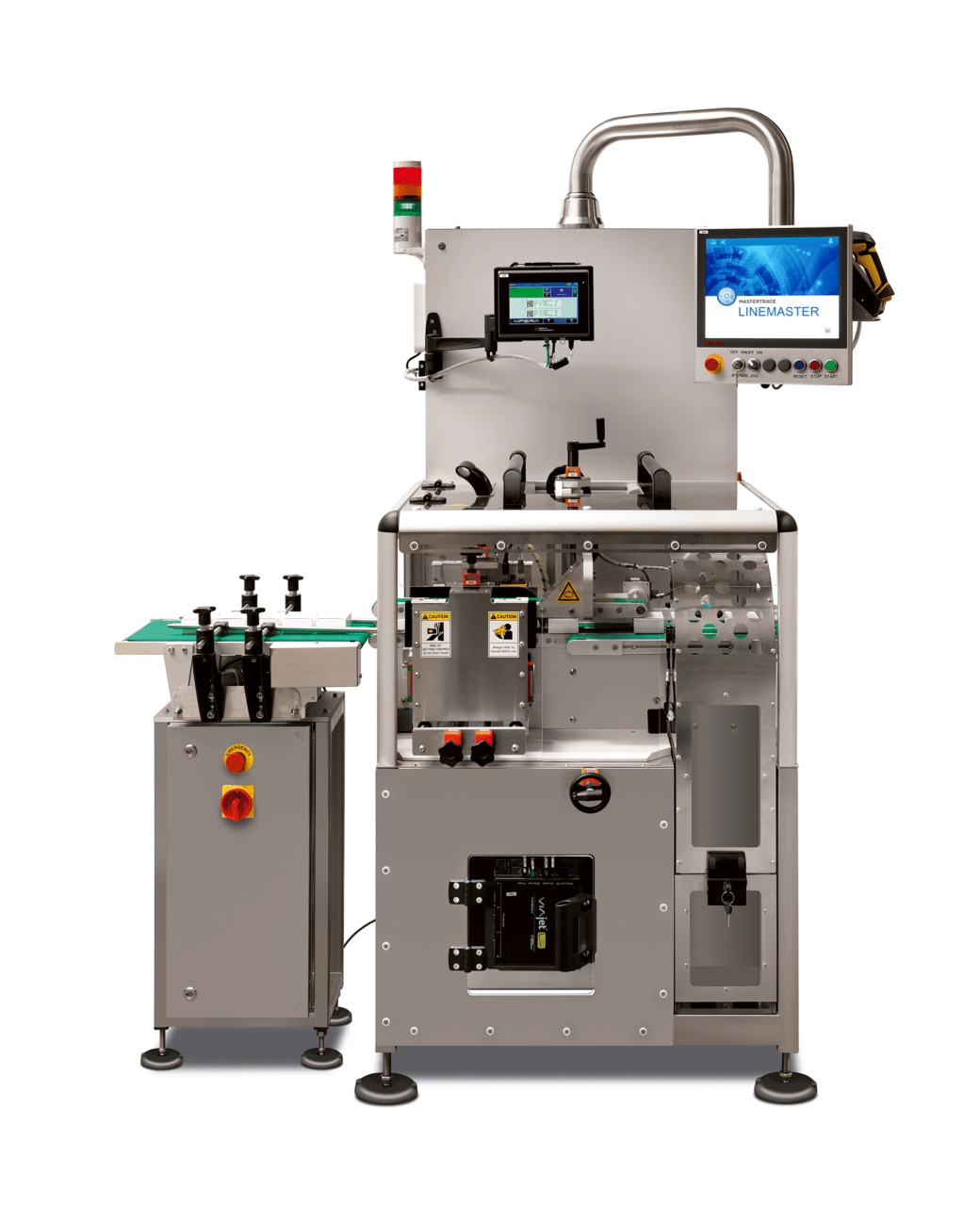

The Masterprint PharmaJet DMP6 labeling, verification and validation system provides a high-quality and user-friendly solution for pharmaceutical manufacturing, distribution and logistics companies, providing 100% of the highest customerproduction requirements in line with the latest European Union (EU FMD), Russian and other national regulations, GS1 guidelines, and high safety standards.