Properly sized labeling according to requirements

The SWING 1 has a maximum printing area of 32mm x 50mm, while the SWING 2 offers a printing area of 53mm x 90mm. The resolution is 300 dpi, and the printing speed can reach up to 220 mm/s (Low-power) or 400 mm/s (High-power). The SWING X 2.40 version is designed for labeling multi-piece or large-sized packages, with a printing area of 53mm x 400mm, while the SWING X 2.60 can produce even larger labels with a size of 53mm x 600mm. The SWING X 22.40 operates with two print heads, allowing for 2 x 53mm x 200mm prints, while the SWING X 22.60 also features dual print heads for placing 2 x 53mm x 300mm labels on products.

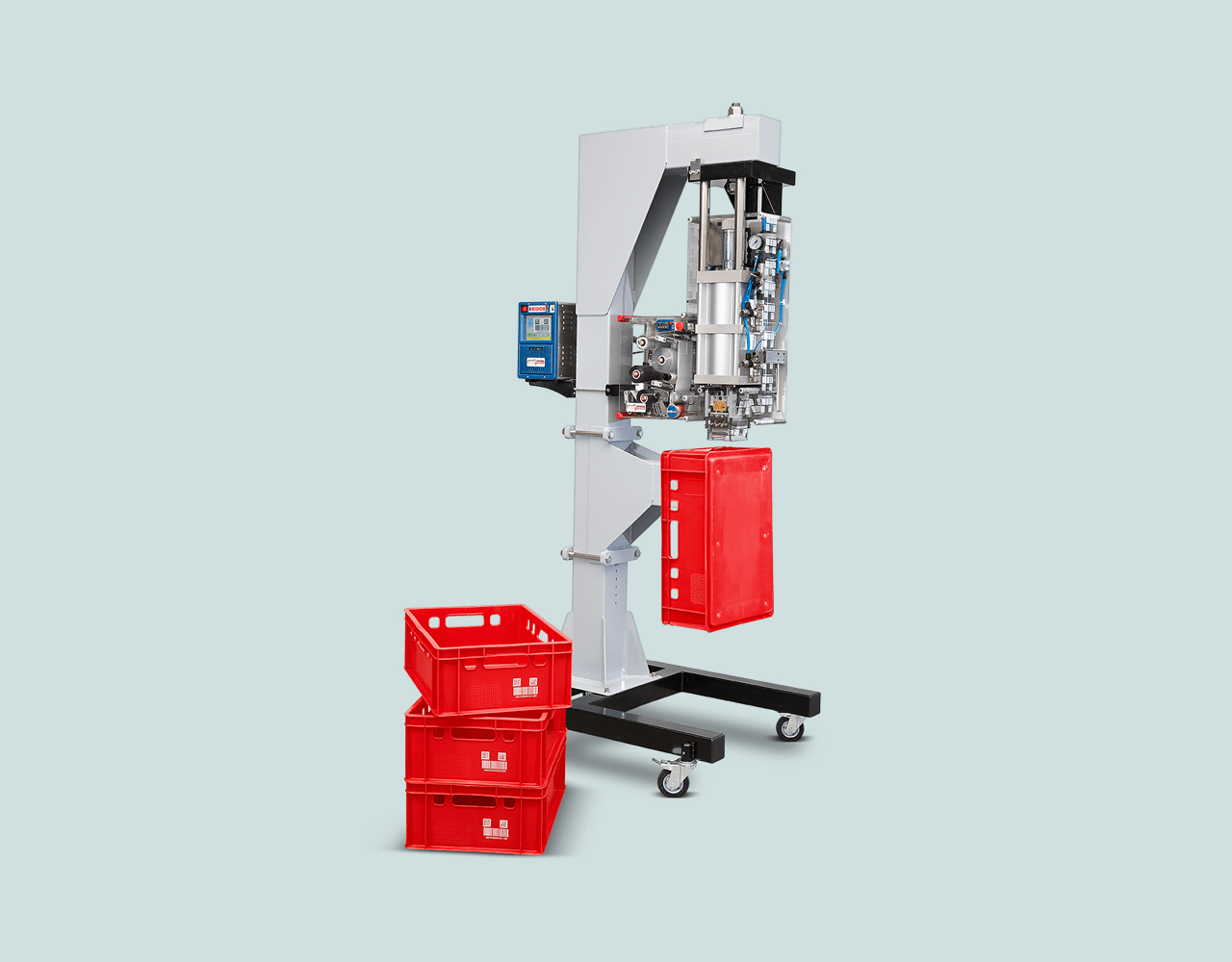

Information is placed on the film using thermal transfer technology with environmentally friendly ink, which dries immediately after printing. It is an optimal choice for the immediate labeling of manufacturing numbers and expiration dates in the food and healthcare industries on the production line.

User-friendly and easy operation

The touchscreen color display facilitates easy device operation. Data and text can be input or retrieved from the device’s memory via USB flash drive, barcode scanner, or connected computer.

Flexibility

Swing devices are available in both continuous mode (where the film moves continuously) and batch mode (where the film temporarily stops for printing). They are designed to operate in harsh conditions, including cold and humid environments often encountered in food packaging. The surface of the packaging does not require pre-treatment, and the marking dries immediately, resulting in long-lasting durability.

Cost-saving devices

Thanks to ribbon-saving operation, efficiency is maximized, and data changes can be made within seconds with minimal downtime. Various ribbons are available in different colors and widths. They can be used with ribbons up to 1000 meters long, and the ribbon replacement process takes only a few seconds.

Fast printing

High printing speed, such as 1000mm/s in Swing 2. Gear mode, does not compromise printing quality. It allows for printing barcodes, 2D codes, logos, ingredient listings, and serialization data at a resolution of 300 dpi.

Swing C – for continuous printing

This series is specifically developed by Eidos for continuous printing of variable data on moving film. Since the speed of the film is not constant, an encoder device needs to be added to the printing roller to synchronize the printing with the incoming film speed. Among the different models, the smallest printing area is 32mm x 50mm, while the largest is 128mm x 400mm. The resolution is 300 dpi, and the printing speed is up to 1000 mm/s.